Clamshell Packaging

A Solution for Every Need and Budget

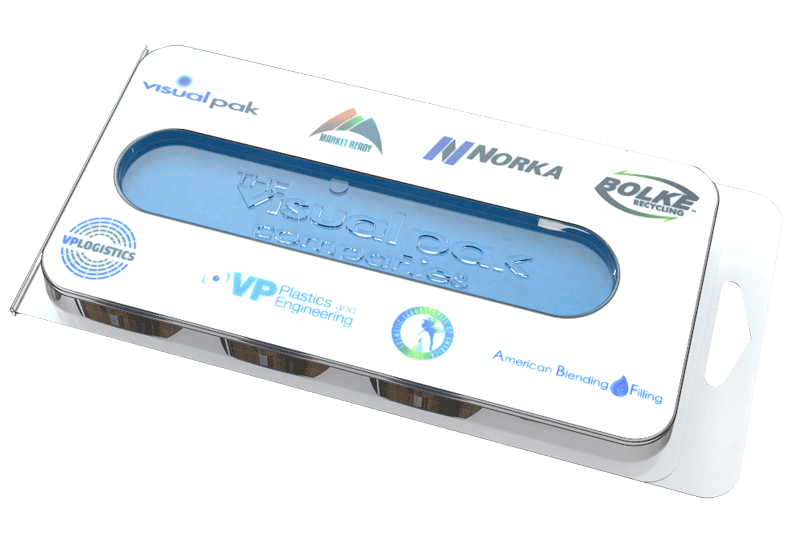

VP Plastics & Engineering full-service thermoforming facility, designs and produces a variety of clamshell packaging to conform to the unique configurations of your product line.

MOCK CLAMSHELLS

Despite the name, a mock clamshell is very similar to a full card blister. The primary difference between the two would be a short platform (usually 1/8” or less), which encapsulates the entire card, with a small flange at the base of the platform. The main purpose of this configuration is to give additional support to the blister card, and help prevent the card from getting ‘dog ears’ from rough handling. This is especially true when a customer has a heavier product on a blister card, where the corners of the card tend to get damaged during handling.

The mock clamshell generally does not suffer from the same warping or curling problem as a full card blister, as the platform lends additional structural strength to the package. Tooling costs can be slightly higher than a standard, trapped, or full card blister, due to the additional material required for the platform portion of the thermoform.

BI-FOLD CLAMSHELLS

Bi-fold clamshells are probably the most common type of hinged closure packaging. Simply put, it is a one-piece design, with a hinge in the middle, allowing the thermoformed part to be closed together and secured. There are a myriad of design options available for this type of part, and the product being packaged usually dictates the design.

The product cavity can be split 50/50, or biased towards the front or back of the package in whatever configuration necessary to meet the customer’s needs. If the package needs to stand at retail, feet can be formed into the part to accommodate this need. Most bi-fold clamshells utilize a snap fit closure, to allow the package to be re-sealed by the end user if needed. These closures can be buttons, channels, or full perimeter snaps.

Depending on which material the part is formed on, clamshells can be heat, radio-frequency, sonic, or ultraviolet-light sealed, but can be utilized at retail with only the formed closures providing security. Tooling for clamshells are generally more costly than any blister type.

TRI-FOLD CLAMSHELLS

Similar to a standard face seal blister, a full card blister is still heat sealed to a blister card. The main difference is that a standard blister has a contour flange (i.e. concentric around the form), whereas a full card blister has a flange area that covers the entire face of the blister card.

Typically, this type of blister is used on products that are abnormally heavy, as a means to reinforce the hang hole area of the card with plastic. Of course, due to the maximized area of plastic, this type of form can be significantly more expensive than a standard blister. Tooling and sealing considerations are essentially the same as a standard blister. One drawback to this type of blister is the tendency of the blister card to warp after being sealed.

The large area that is usually sealed in this configuration causes the card to bow or warp, which affects the aesthetics of the package, as well as potentially causing problems in production and pack off.