Blister Packaging Solutions

A Multitude of Blister Possibilities

From standard face seal blisters to full card blisters, the possibilies are endless. VP Plastics and Engineering can take your packaging to another level. Whether you need a refresh on design or starting from scratch, we’re here for you.

STANDARD FACE SEAL BLISTERS

Blisters face seal blisters used to be the most common type of thermoformed packaging, mainly due to the cost. The larger the part, the more expensive, and a single piece face seal blister covers the least amount of real estate. Simply put, a face seal blister is a form that encompasses the body of a product, and heat seals to a specially treated card, utilizing the flanges on the blister. Minimum recommended lange size is 1/4″, but we usually suggest 5/16”.

For products that are heavier than normal, a larger flange is recommended. Typically, the tooling portion of a blister is more cost effective than other packaging options, such as clamshells, but thought has to be given to the cost of the heat seal tooling that is necessary with this type of packaging. Depending on the machine being used to seal the blisters, the heat seal tooling can be more costly than the entire thermoform tool.

TRAPPED BLISTERS

A trapped blister is essentially the same thing as a face seal blister, but usually with a larger flange. The flange is utilized to trap the blister between two cards, or pieces of corrugate, with glue being used to seal the card or corrugate together. This type of package is becoming increasingly popular, due to the perception of it being more ecologically friendly. It also doesn’t require heat seal tooling, and can even be packaged in a ‘table top’ operation for smaller customers.

The tooling portion of this type of thermoform is the same in design, function, and cost as a face seal blister. Flange size for most trapped blisters start at 3/8”, and increase with the weight of the product being encapsulated.

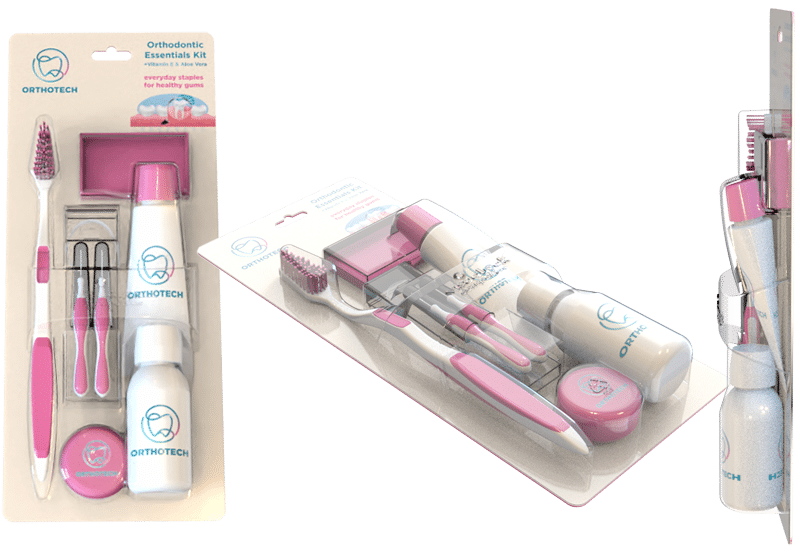

FULL CARD BLISTERS

Similar to a standard face seal blister, a full card blister is still heat sealed to a blister card. The main difference is that a standard blister has a contour flange (i.e. concentric around the form), whereas a full card blister has a flange area that covers the entire face of the blister card.

Typically, this type of blister is used on products that are abnormally heavy, as a means to reinforce the hang hole area of the card with plastic. Of course, due to the maximized area of plastic, this type of form can be significantly more expensive than a standard blister. Tooling and sealing considerations are essentially the same as a standard blister. One drawback to this type of blister is the tendency of the blister card to warp after being sealed.

The large area that is usually sealed in this configuration causes the card to bow or warp, which affects the aesthetics of the package, as well as potentially causing problems in production and pack off.