Blisters, Inc., The Visual Pak Companies' full-service thermoforming facility, designs and produces custom packaging to conform to the unique configurations of your particular product line:

Our machine shop

Commonly used thermoforming material |

We currently have multiple production lines with formers including trim and stack capability, as well as 30" x 48" form and trim lines. The basic function of each thermoformer is essentially the same, with forming area being the primary difference between lines. All formers utilize both vacuum and air pressure to form parts. Some thermoformers use only vacuum, which can have an effect on the distribution of plastic, as well as the form detail on the part. In addition, we have a sample machine that we use for prototyping. |

|

| |

|

|

| Our products |

|

Standard Face Seal

Blisters face seal blisters used to be the most common type of thermoformed packaging, mainly due to the cost. The larger the part, the more expensive, and a single piece face seal blister covers the least amount of real estate. Simply put, a face seal blister is a form that encompasses the body of a product, and heat seals to a specially treated card, utilizing the flanges on the blister. Minimum recommended lange size is ¼”, but we usually suggest 5/16”.

For products that are heavier than normal, a larger flange is recommended. Typically, the tooling portion of a blister is more cost effective than other packaging options, such as clamshells, but thought has to be given to the cost of the heat seal tooling that is necessary with this type of packaging. Depending on the machine being used to seal the blisters, the heat seal tooling can be more costly than the entire thermoform tool.

Trapped Blisters

A trapped blister is essentially the same thing as a face seal blister, but usually with a larger flange. The flange is utilized to trap the blister between two cards, or pieces of corrugate, with glue being used to seal the card or corrugate together. This type of package is becoming increasingly popular, due to the perception of it being more ecologically friendly. It also doesn't require heat seal tooling, and can even be packaged in a ‘table top’ operation for smaller customers.

The tooling portion of this type of thermoform is the same in design, function, and cost as a face seal blister. Flange size for most trapped blisters start at 3/8”, and increase with the weight of the product being encapsulated.

Full Card Blisters

Similar to a standard face seal blister, a full card blister is still heat sealed to a blister card. The main difference is that a standard blister has a contour flange (i.e. concentric around the form), whereas a full card blister has a flange area that covers the entire face of the blister card.

Typically, this type of blister is used on products that are abnormally heavy, as a means to reinforce the hang hole area of the card with plastic. Of course, due to the maximized area of plastic, this type of form can be significantly more expensive than a standard blister. Tooling and sealing considerations are essentially the same as a standard blister. One drawback to this type of blister is the tendency of the blister card to warp after being sealed.

The large area that is usually sealed in this configuration causes the card to bow or warp, which affects the aesthetics of the package, as well as potentially causing problems in production and pack off. |

| |

|

|

| |

|

|

Mock Clamshells

Despite the name, a mock clamshell is very similar to a full card blister. The primary difference between the two would be a short platform (usually 1/8” or less), which encapsulates the entire card, with a small flange at the base of the platform. The main purpose of this configuration is to give additional support to the blister card, and help prevent the card from getting ‘dog ears’ from rough handling. This is especially true when a customer has a heavier product on a blister card, where the corners of the card tend to get damaged during handling.

The mock clamshell generally does not suffer from the same warping or curling problem as a full card blister, as the platform lends additional structural strength to the package. Tooling costs can be slightly higher than a standard, trapped, or full card blister, due to the additional material required for the platform portion of the thermoform.

[ Top of page ] |

| |

|

|

| |

|

|

Bi-fold Clamshells

Bi-fold clamshells are probably the most common type of hinged closure packaging. Simply put, it is a one-piece design, with a hinge in the middle, allowing the thermoformed part to be closed together and secured. There are a myriad of design options available for this type of part, and the product being packaged usually dictates the design.

The product cavity can be split 50/50, or biased towards the front or back of the package in whatever configuration necessary to meet the customer’s needs. If the package needs to stand at retail, feet can be formed into the part to accommodate this need. Most bi-fold clamshells utilize a snap fit closure, to allow the package to be re-sealed by the end user if needed. These closures can be buttons, channels, or full perimeter snaps.

Depending on which material the part is formed on, clamshells can be heat, radio-frequency, sonic, or ultraviolet-light sealed, but can be utilized at retail with only the formed closures providing security. Tooling for clamshells are generally more costly than any blister type.

[ Top of page ] |

| |

|

|

| |

|

|

Two-Piece Clamshells

Two piece clamshells are essentially the same as a bi-fold clamshell, with the elimination of the hinge being the only difference. This type of clamshell can be used if the customer wants the front and back portion of the clamshell formed from different material thicknesses, or if the hinge on a standard bi-fold clamshell interferes with a design feature required for the package.

While two-piece clamshells provide slightly more flexibility in the layout of the mold, there are drawbacks inherent in this design as well. The handling of two separate pieces, both during production, as well as pack off at the customer’s end, can increase overall labor costs for the package. There is no real cost difference between a standard bi-fold, and a two-piece clamshell, in piece price, or tooling costs.

[ Top of page ] |

| |

|

|

| |

|

|

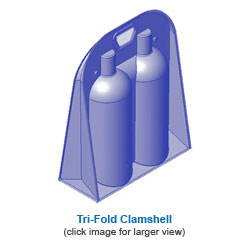

Tri-fold Clamshells

A tri-fold clamshell is probably the most costly packaging option, at least in terms of hinged clamshell packaging. A tri-fold clamshell incorporates two hinges, with a triangulated formed portion between the hinges, which, when both cavity sides of the clamshells are folded together, meet with the center portion to create a stable package capable of standing at retail.

Typically, the center portion is equal to, or greater than the depth of the thickest portion of the product being encapsulated. When the clamshell is in the open position, this adds that amount to the overall length of the part, and therefore to the cost. Tooling costs are also significantly higher than any other package type that we produce.

Sealing options are similar to other types of clamshells, again, dependent on the type of material used in forming. This type of package is usually necessary when the product being displayed would be unstable with a standard bi-fold in the standing position, due to a high center of gravity

[ Top of page ] |

| |

|

|

| |

|

|

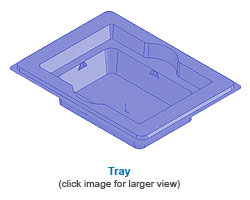

Trays

Trays are typically used in conjunction with a folding carton or other type of box, for a wide range of products and applications. Game trays, dunnage trays, storage trays, and display trays are some of the more common applications we produce trays for. We also manufacture POP display trays for use at retail counters.

[ Top of page ]

|

|